Optics

Beam shaper [GTH]

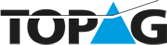

GTH-S-4.0-2.0

- - Square Top Hat

- - > 95 % efficiency

- - 100 µm to 5 mm Top Hat width

- - coatings for UV to IR

- - 4 mm input beam diameter, 2 mrad fan angle

SPECIFICATIONS

| SPOT GEOMETRY | |

|---|---|

| Top Hat width | full fan angle of 2 mrad |

| Efficiency | > 95% (depends on the coating type) |

| Homogeneity | about ± 5% (rel. to average intensity of the Top Hat plateau) |

| Depth of the Top Hat shape (DOF) | Depends on the optical setup; for example 1.5mm depth using 4.0mm beam diameter, wavelength 532nm and 250mm focal length. |

| REQUIREMENTS FOR THE USE OF GTH-S-5.0-16.0 | |

| Input beam | single or multimode laser beam with Gaussian energy distribution |

| Input beam diameter | 4.0 mm @1/e² |

| Apertures within the optical setup | clear aperture along the whole beam path should be at least 2.5x larger than the beam diameter @ 1/e² |

| INTEGRATION OF GTH-S-5.0-16.0 INTO THE BEAM PATH | |

| Alignment | alignment in lateral direction is necessary (translation). Rotating the shaper around the optical axis is helpful to align the orientation of the Top Hat. We recommend our mount HSF02. |

| Optical equipment |

required: focusing optic to generate the Top Hat in the focal plane of this optic. useful: beam expander to firstly adjust the effective beam dia. to the design input beam dia. of GTH-S-4.0-2.0 and secondly adjust the beam dia. to the desired spot size. helpful: beam profiler to check profiles while aligning. |

| SUBSTRATE SPECIFICATIONS | |

| Material | fused silica |

| Dimension1) | dia. 1 inch x 3 mm |

| Standard AR/AR coatings1), transmission and laser damage threshold |

@ UV 210 – 400 nm; T > 96%; LDT 1 J/cm² @ 10 ns @ VIS 400 – 700 nm; T > 98%; LDT 2 J/cm² @ 10 ns @ IR 650 – 1100 nm; T > 98,5%; LDT 3 J/cm² @ 10 ns |

| ORDER INFORMATION | |

| Product code | GTH-S-4.0-2.0- AR coating type |

| Example | GTH-S-4.0-2.0-VIS → GTH-S-4.0-2.0 including AR @ 400 – 700 nm |

| 1) Others on request | |

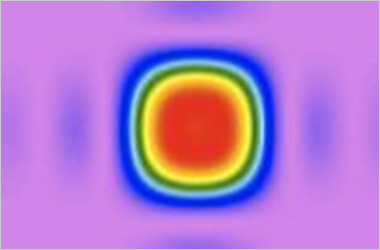

GTH-S-4.0-6.0

- - Square Top Hat

- - > 95 % efficiency

- - 300 µm to 15 mm Top Hat width

- - coatings for UV to IR

- - 4 mm input beam diameter, 6 mrad fan angle

SPECIFICATIONS

| SPOT GEOMETRY | |

|---|---|

| Top Hat width | full fan angle of 6 mrad |

| Efficiency | > 95% (depends on the coating type) |

| Homogeneity | about ± 5% (rel. to average intensity of the Top Hat plateau) |

| Depth of the Top Hat shape (DOF) | Depends on the optical setup; for example 3.5mm depth using 4.0mm beam diameter, wavelength 532nm and 250mm focal length. |

| REQUIREMENTS FOR THE USE OF GTH-S-5.0-16.0 | |

| Input beam | single or multimode laser beam with Gaussian energy distribution |

| Input beam diameter | 4.0 mm @1/e² |

| Apertures within the optical setup | clear aperture along the whole beam path should be at least 2.5x larger than the beam diameter @ 1/e² |

| INTEGRATION OF GTH-S-5.0-16.0 INTO THE BEAM PATH | |

| Alignment | alignment in lateral direction is necessary (translation). Rotating the shaper around the optical axis is helpful to align the orientation of the Top Hat. We recommend our mount HSF02. |

| Optical equipment |

required: focusing optic to generate the Top Hat in the focal plane of this optic. useful: beam expander to firstly adjust the effective beam dia. to the design input beam dia. of GTH-S-4.0-6.0 and secondly adjust the beam dia. to the desired spot size. helpful: beam profiler to check profiles while aligning. |

| SUBSTRATE SPECIFICATIONS | |

| Material | fused silica |

| Dimension1) | dia. 1 inch x 3 mm |

| Standard AR/AR coatings1), transmission and laser damage threshold |

@ UV 210 – 400 nm; T > 96%; LDT 1 J/cm² @ 10 ns @ VIS 400 – 700 nm; T > 98%; LDT 2 J/cm² @ 10 ns @ IR 650 – 1100 nm; T > 98,5%; LDT 3 J/cm² @ 10 ns |

| ORDER INFORMATION | |

| Product code | GTH-S-4.0-6.0- AR coating type |

| Example | GTH-S-4.0-6.0-VIS → GTH-S-4.0-6.0 including AR @ 400 – 700 nm |

| 1) Others on request | |

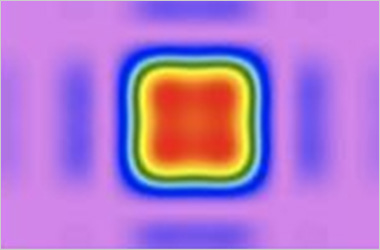

GTH-S-5.0-16.0

- - Square Top Hat

- - > 95 % efficiency

- - 800 µm to 40 mm Top Hat width

- - coatings for UV to IR

- - 5 mm input beam diameter, 16 mrad fan angle

SPECIFICATIONS

| SPOT GEOMETRY | |

|---|---|

| Top Hat width | full fan angle of 16 mrad |

| Efficiency | > 95% (depends on the coating type) |

| Homogeneity | about ± 5% (rel. to average intensity of the Top Hat plateau) |

| Depth of the Top Hat shape (DOF) | Depends on the optical setup; for example 4mm depth using 5.0mm beam diameter, wavelength 532nm and 250mm focal length. |

| REQUIREMENTS FOR THE USE OF GTH-S-5.0-16.0 | |

| Input beam | single or multimode laser beam with Gaussian energy distribution |

| Input beam diameter | 5.0 mm @1/e², tolerance ± 0.1 mm |

| Apertures within the optical setup | clear aperture along the whole beam path should be at least 2.5x larger than the beam diameter @ 1/e² |

| INTEGRATION OF GTH-S-5.0-16.0 INTO THE BEAM PATH | |

| Alignment | alignment in lateral direction is necessary (translation). Rotating the shaper around the optical axis is helpful to align the orientation of the Top Hat. We recommend our mount HSF02. |

| Optical equipment |

required: focusing optic to generate the Top Hat in the focal plane of this optic. useful: beam expander to firstly adjust the effective beam dia. to the design input beam dia. of GTH-S-5.0-16.0 and secondly adjust the beam dia. to the desired spot size. helpful: beam profiler to check profiles while aligning. |

| SUBSTRATE SPECIFICATIONS | |

| Material | fused silica |

| Dimension1) | dia. 1 inch x 3 mm |

| Standard AR/AR coatings1), transmission and laser damage threshold |

@ UV 210 – 400 nm; T > 96%; LDT 1 J/cm² @ 10 ns @ VIS 400 – 700 nm; T > 98%; LDT 2 J/cm² @ 10 ns @ IR 650 – 1100 nm; T > 98,5%; LDT 3 J/cm² @ 10 ns |

| ORDER INFORMATION | |

| Product code | GTH-S-5.0-16.0- AR coating type |

| Example | GTH-S-5.0-16.0-VIS → GTH-S-5.0-16.0 including AR @ 400 – 700nm |

| 1) Others on request | |

Beam shaper [FBS]

| Parameters | |

|---|---|

| Efficiency | > 95% of input energy within Top Hat profile |

| Transmission | > 99%, incl. AR/AR coating |

| Material | UV Fused Silica |

| Dimensions | dia. 25.4mm/thickness 3mm |

| Damage threshold | 4J/cm² @ 532nm and 10ns |

| Select beam diameter d (@1/e2) | 1.0, 1.5 … 10.0mm |

| Tolerance for input beam diameter | < ±10% |

| Select wavelength/AR coating (standard) | 1064/1030nm, 532/515nm, 355/343nm |

| Others sizes and wavelengths on request | |

| Model No: FBS-beam diameter-wavelength | |

| Parameters | |

|---|---|

| Efficiency | > 90% of input energy within Top Hat profile |

| Transmission | > 99%, incl. AR/AR coating |

| Material | UV Fused Silica |

| Dimensions | dia. 25.4mm/thickness 3mm |

| Damage threshold | 4J/cm² @ 532nm and 10ns |

| Select beam diameter d (@1/e2) | 1.0, 1.5 … 10.0mm |

| Tolerance for input beam diameter | < ±10% |

| Select wavelength/AR coating (standard) | 1064/1030nm, 532/515nm, 355/343nm |

| Others sizes and wavelengths on request | |

| Model No: FBS2-beam diameter-wavelength | |

| Parameters | |

|---|---|

| Efficiency | > 95% of input energy within Top Hat profile |

| Transmission | > 99%, incl. AR/AR coating |

| Material | UV Fused Silica |

| Dimensions | dia. 25.4mm/thickness 3mm |

| Damage threshold | 4J/cm² @ 532nm and 10ns |

| Select beam diameter d (@1/e2) | 1.0, 1.5 … 10.0mm |

| Tolerance for input beam diameter | < ±10% |

| Select wavelength/AR coating (standard) | 1064/1030nm, 532/515nm, 355/343nm |

| Others sizes and wavelengths on request | |

| Model No: FBSR-beam diameter-wavelength | |

Beam splitter

1-dimensional

| Model | Efficiency | Product sheet | |

|---|---|---|---|

| DBS-1X2 |

|

80 | |

| DBS-1X3 |

|

84 | |

| DBS-1X5 |

|

71 | |

| DBS-1X6 |

|

80 | |

| DBS-1X7 |

|

74 | |

| DBS-1X8 |

|

70 | |

| DBS-1X9 |

|

73 | |

2-dimensional

| Model | Efficiency | Product sheet | |

|---|---|---|---|

| DBS-2X2 |

|

66 | |

| DBS-3X3 |

|

73 | |

| DBS-3X5 |

|

75 | |

| DBS-4X4 |

|

74 | |

| DBS-5X5 |

|

74 | |

| DBS-8X8 |

|

75 | |

| DBS-5/4 |

|

72 | |

| DBS-7/6 |

|

75 | |

| DBS-8/4 |

|

70 | |

Mirrors for ultra fast

| Wavelength range | 190-3000 nm |

|---|---|

| Dimension | 5-200 mm |

| Shape | Round, rectangular, eliptical |

| Surface quality, S-D | 10-5* |

| Surface flatness, P-V | <λ/10 @ 632.8 nm* |

| Reflectance | >99.8% |

| LIDT | >20 J/cm² @ 1064 nm, 10 ns, 10 Hz |

*depending on size