Key benefits of the HDO

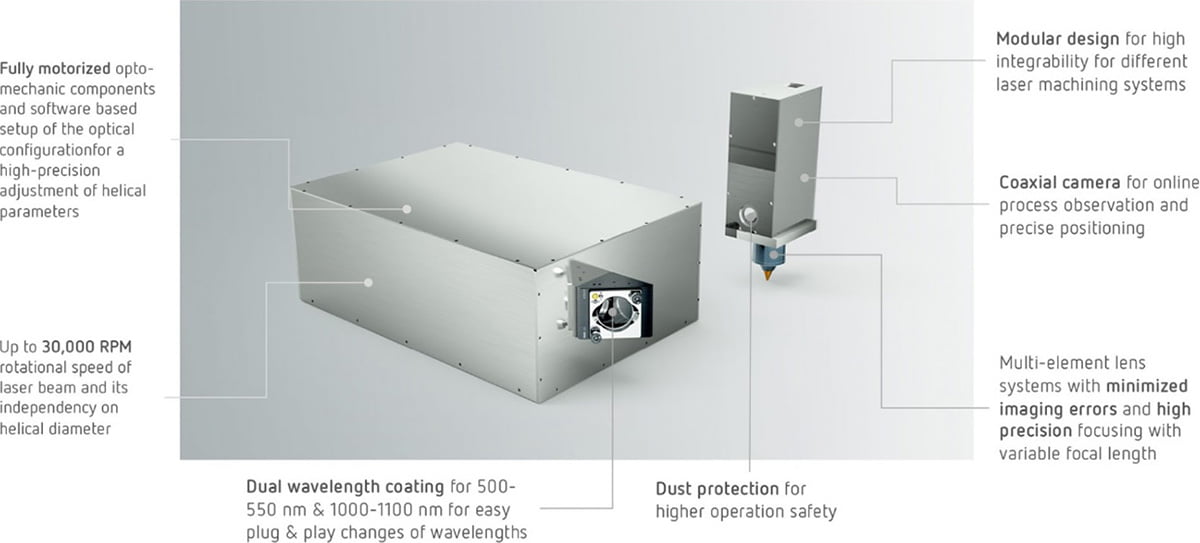

- High integrability for different laser machining systems by a modular design consisting of a rotation module and processing head

- High precision of the hole shape and cutting kerf

- High aspect-ratio with a well-defined hole profile due to the selfrotation of the laser spot while moving on the helical path

- High productivity enabled by rotational speed of laser beam up to 30,000 RPM and its independency on helical diameter

- Dual wavelength coating for 500-550 nm & 1000-1100 nm for easy plug & play switches of wavelengths

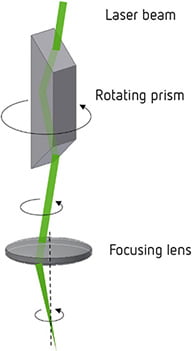

Principle of operation

The helical drilling optics consists of a beam rotator, optical components for beam tilt and parallel shift.

The laser beam is rotated around the optical axis by the beam rotator – a Dove prism mounted in a high-speed hollow shaft motor,

and the emitted laser beam spins in a circular path with respect to the workpiece surface. If the outgoing laser beam is offset or tilted

from the optical axis, a micro-hole with a certain taper or diameter is fabricated. With the control software, the diameter and taper

of the micro-hole can be changed precisely. The use of Dove prisms as image rotators has the fundamental advantage that

the drilling quality does not depend on the laser beam cross-sectional characteristics.

Also, due to the prism imaging characteristics, the outgoing laser beam rotates at twice the motor operating rate,

increasing drilling efficiency.

Main features

Modular design

High integrability for different laser machining systems

Rotation module

- Dimensions: LxWxH 555x370x195 mm³

- Weight: 30 kg

- Maximum beam rotation speed: 30,000 rpm

- AC hollow motor with encoder for a position, speed and temperature feedback,

water cooling optional - Fused silica optics set with dual-wavelength coating

- Achievable helical diameter: 5-1000 µm

- Achievable taper: max ±15°

- Automated control of rotator: adjustment accuracy 0.75 arcmin

- Motorized beam deflection and translation reflector

Focusing/machining module

- Dimensions: LxWxH 145x105x280 mm³

- Weight: 4 kg

- Coaxial CMOS camera

- Real-time machining positioning and observation

- Fixed focus optics, focal lengths of 30, 60, 120, 150 mm, etc.

- Highest stability and best repeatability

- Applicable wavelengths: 355 nm, 532 nm, and 1064 nm

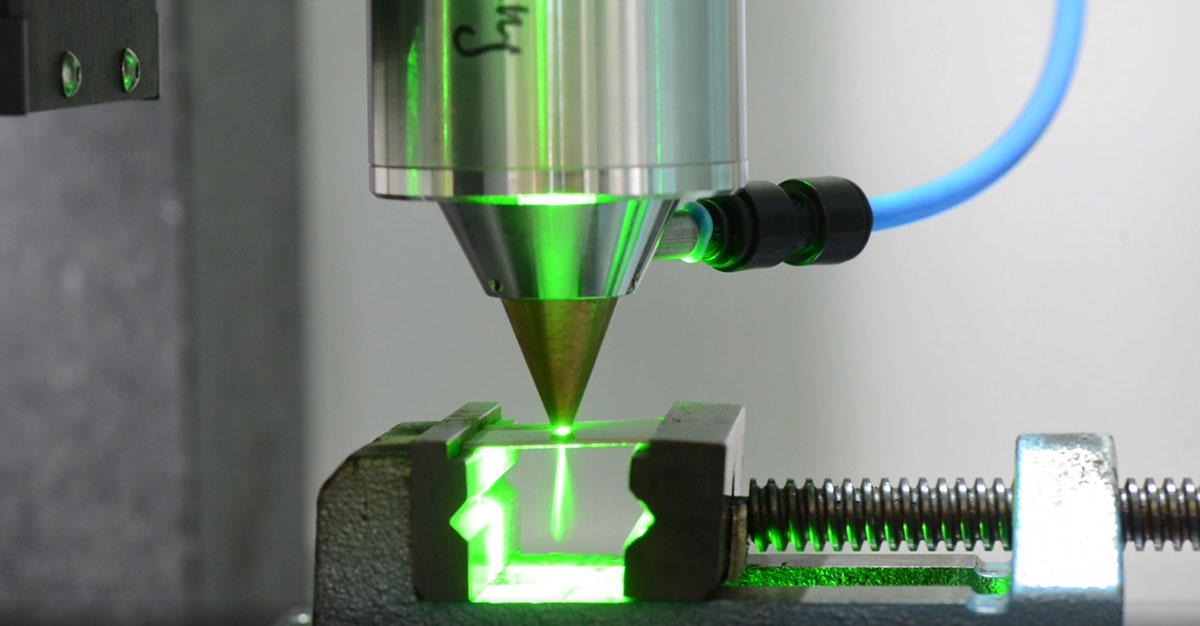

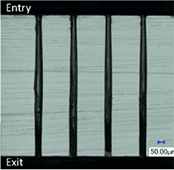

Helical drilling process

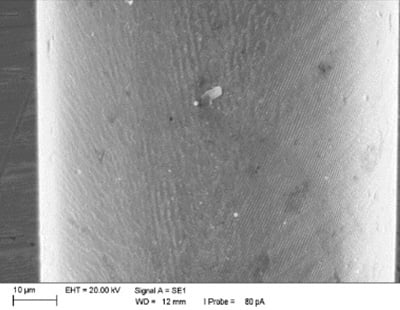

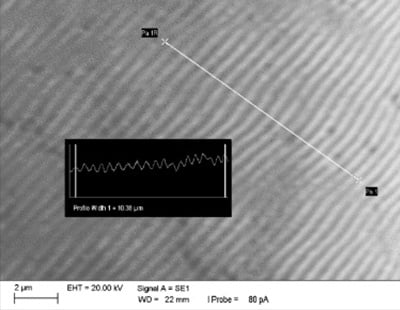

Drilling in 0.5 mm thick stainless steel

Advantages of helical drilling

Based on Ø100 µm drilling in 1 mm thick stainless steel, quality prioritized

| Parameter | Helilcal drilling | long pulse drilling | EDM |

|---|---|---|---|

| Drilling speed | 1 sec./hole | 0.3 sec./hole | 0.5 sec./hole |

| Precision | < 1 µm | ~5 µm | > 30 µm |

| HAZ | negligible | 5 µm | 20 µm |

| Aspect ratio | 50:1 | 10:1 | 10:1 |

| Conicity | -14°~15° | 3-15° | 3-8° |

| Roughness of the drill wall | < 0.2 µm | 2 µm | 10 µm |

| Roundness of the drill exit | > 0.95 | ~0.65 | 0.75 |

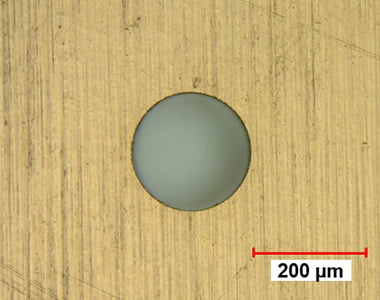

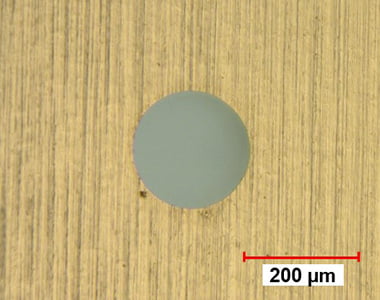

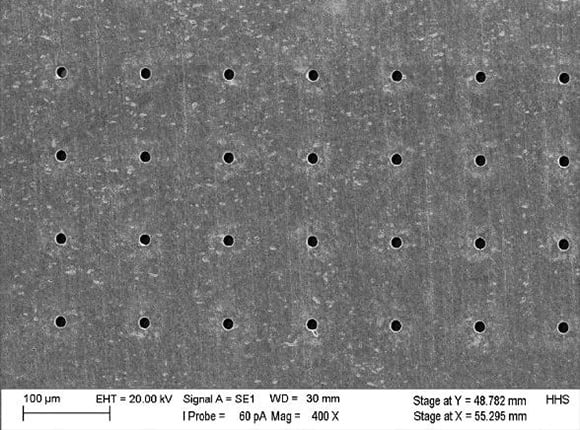

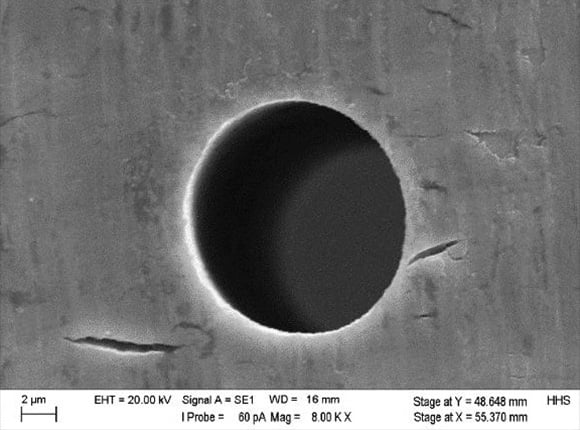

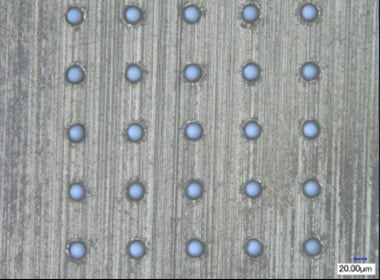

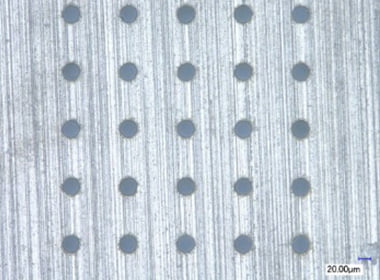

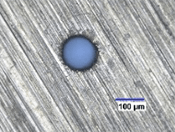

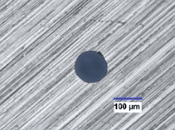

High precision microholes in stainless steel

-

Entry

-

Exit

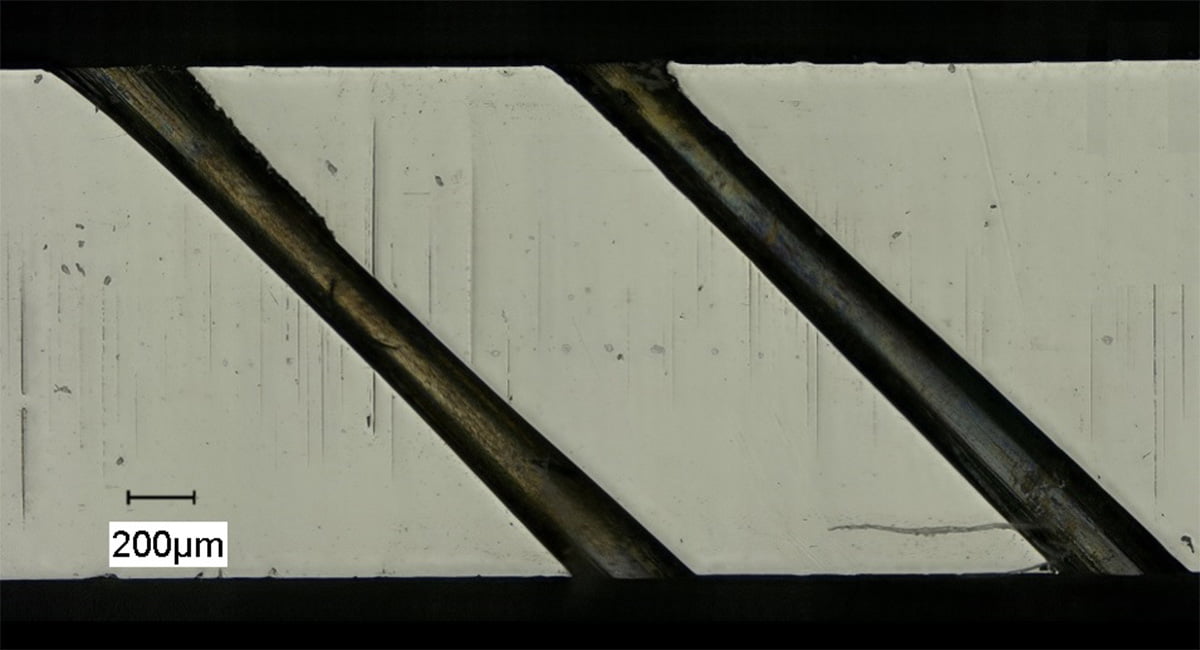

Shaped holes drilling in stainless steel

Helical drilling of micro holes with different taper

-

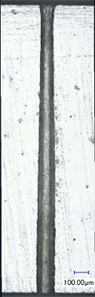

10 μm micro holes in 100 μm titanium

-

Single hole

Silicone Wafer

Overview |

Single hole |

|

|---|---|---|

Entry |

|

|

Exit |

|

|

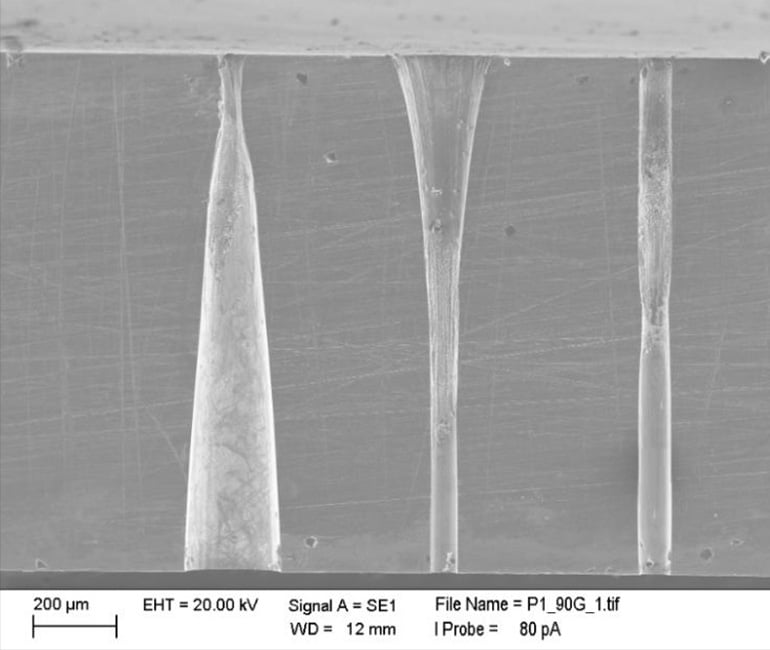

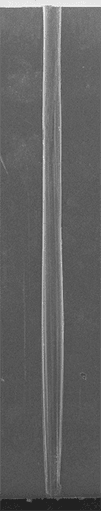

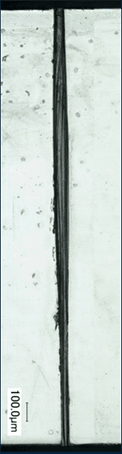

Helical drilling with high aspect-ratio in stainless

1 mm Material thickness |

2 mm Material thickness |

3 mm Material thickness |

|||

|---|---|---|---|---|---|

| 10:1 | 20:1 | 20:1 | 30:1 | 50:1 | |

|

|

|

|

|

|

Helical cutting of sapphire glass